Chris BaraniukKnow-how Reporter

Boston Metallic

Boston MetallicAn exercise centre for infants and toddlers, an Indian restaurant, an indoor golf centre – and a mini experimental metal plant. These companies are amongst those who make up a small retail and industrial property within the metropolis of Woburn, Massachusetts.

“Persons are dropping off their children. That sort of reveals you an excessive instance of what the way forward for metal appears to be like like,” says Adam Rauwerdink, vice chairman of enterprise growth at US-based inexperienced metal start-up, Boston Metallic. “You could be making metal and sharing a car parking zone with a daycare.”

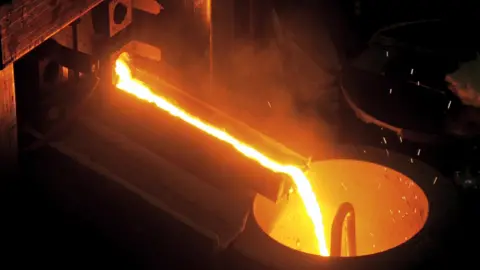

Boston Metallic has give you a means of utilizing electrical energy to take away oxides and different contaminants from iron ore, which is the substance it’s a must to mine from the Earth earlier than you may make new metal.

The method entails distributing the ore inside an electrolyte after which utilizing electrical energy to warmth this combination to 1,600C. Molten iron then separates from impurities and could be tapped off.

Historically, extracting that all-important iron from ores requires blast furnaces that run on fossil fuels. However the iron and metal business are responsible for 11% of world emissions – an enormous quantity, equal to all the world’s private cars and vans – and so now a race is on to seek out greener methods of manufacturing these vital metals.

US firms are, arguably, on the forefront. Steelmaking within the US is already greener than in lots of international locations, because of the recognition of electric arc furnaces there. These furnaces use electrical energy, not warmth from burning fossil fuels, to soften scrap metal – for instance – and recycle it.

Plus, a handful of rising start-ups akin to Boston Metallic say they’ll go one higher and use electrical energy for the iron-making course of, an important step in making model new, or virgin, metal.

Nonetheless, the Trump administration has taken a less than enthusiastic stance in the direction of renewable vitality and decarbonisation initiatives. It stays to be seen whether or not these new start-ups will make a giant, molten splash within the metal business any time quickly.

Switching from conventional blast furnaces to electrical arc furnaces can lower carbon emissions per tonne of metal produced from 2.32 tonnes of CO2 to 0.67 tonnes of CO2.

For iron-making, some crops might use inexperienced hydrogen – made utilizing electrical energy from 100% renewable sources – says Simon Nicholas, lead metal analyst on the Institute for Power Economics and Monetary Evaluation.

However switching iron and steel-making crops over to inexperienced hydrogen hasn’t gone as easily as some had anticipated.

In June, Cleveland-Cliffs, a serious US metal producer, appeared to back away from its plans to construct a $500m (£375m) hydrogen-powered metal plant in Ohio. The BBC has contacted Cleveland-Cliffs for remark.

“We’re seeing initiatives cancelled, proponents pulling out of initiatives in all places,” says Mr Nicholas, of inexperienced hydrogen initiatives, particularly.

Bloomberg through Getty Photos

Bloomberg through Getty PhotosPlus, there’s a restrict to how a lot steel-making can depend on electrical arc furnaces since they presently largely rely on a supply of scrap metal.

A comparatively low provide of scrap metal in China, versus demand, has slowed the rollout of electrical arc furnaces there, according to some analyses.

These complications would recommend that there’s a area of interest for firms growing alternative routes of creating iron and metal. Boston Metallic is one.

“It appears to be like rather a lot like how we make iron and metal at this time – it is rather a lot simpler to conceive how that will get to scale [as a result],” says Paul Kempler, an professional in electrochemistry and electrochemical engineering on the College of Oregon.

Nonetheless, he notes that there are nonetheless challenges in guaranteeing that electrolysis techniques like this do not corrode too shortly over time. Boston Metallic says it hopes to have its first demonstration-scale metal plant operational by 2028.

Electra

ElectraIndividually, the US agency Electra is taking a unique method to producing extremely purified iron from ores. In contrast to Boston Metallic, Electra’s course of runs at a comparatively low temperature, round 60-100C. First, iron ore is dissolved into an acidic resolution after which {an electrical} cost causes the iron to gather onto metallic plates. That is much like the method presently used for making sheets of copper and zinc at this time.

“These plates are extracted mechanically out of the answer and the iron is harvested,” says Sandeep Nijhawan, co-founder and chief government. An indication plant in Colorado, which might produce 500 tonnes of iron yearly, is presently set to open subsequent 12 months.

Initially, iron produced on this method would value greater than iron made utilizing conventional strategies. However that “inexperienced premium” might fall away ought to the corporate be capable of scale sufficiently, says Mr Nijhawan.

Bloomberg through Getty Photos

Bloomberg through Getty PhotosMr Nicholas says that rising applied sciences akin to this are hopeful, however one problem they face is in breaking into the market in a giant means inside just some years, since the necessity to slash emissions and curb local weather change is turn out to be an increasing number of pressing: “We’re operating in need of time for addressing carbon emissions.”

Firms akin to Electra and Boston Metallic supply a totally totally different imaginative and prescient of the steel-making business however they will not get far with out additional funding – and a market that appreciates what they’re doing.

President Donald Trump’s tariffs on metal imports to the US are supposedly designed to guard the home metal business – and but they danger elevating the price of metal considerably for US clients.

I ask whether or not Dr Rauwerdink, for one, is pleased to see this transfer, or not. “We’re fairly pleased to see the robust deal with essential metals,” he says, arguing the tariffs are “useful” for Boston Metallic.

Although he acknowledges that US authorities’s perspective in the direction of renewable electrical energy, which Boston Metallic says it wish to prioritise as an vitality supply, has modified these days. And, globally, protecting the price of renewable vitality low is vital for any agency hoping to impress industries beforehand dominated by fossil fuels.

“The business has rising pains there, for certain,” he says.