Lithium-ion batteries’ potential to ship plenty of energy from a small bundle have made them the go-to for makers and producers alike. It’s commonplace now to seek out, say, microcontroller boards with integrated Li-ion chargers. Lithium-ion is so popular, actually, that it’s simple to neglect that different battery applied sciences exist, even once they’re a greater match.

These worthy options embrace detachable rechargeable nickel–metal hydride batteries. Whereas NiMH cells can’t be recharged as many occasions as lithium-ion cells can and don’t provide the identical power density, they’re cheaper and likewise safer. No must ship them in packing containers emblazoned with fire warning labels. The truth that NiMH cells ship decrease voltages than lithium has grow to be much less of a problem because the voltage calls for of integrated circuits have fallen, with 3.3-volt and 1.8-V chips quickly displacing the ever present 5-V commonplace of yesteryear.

Methods to Make NiMH Simpler to Handle

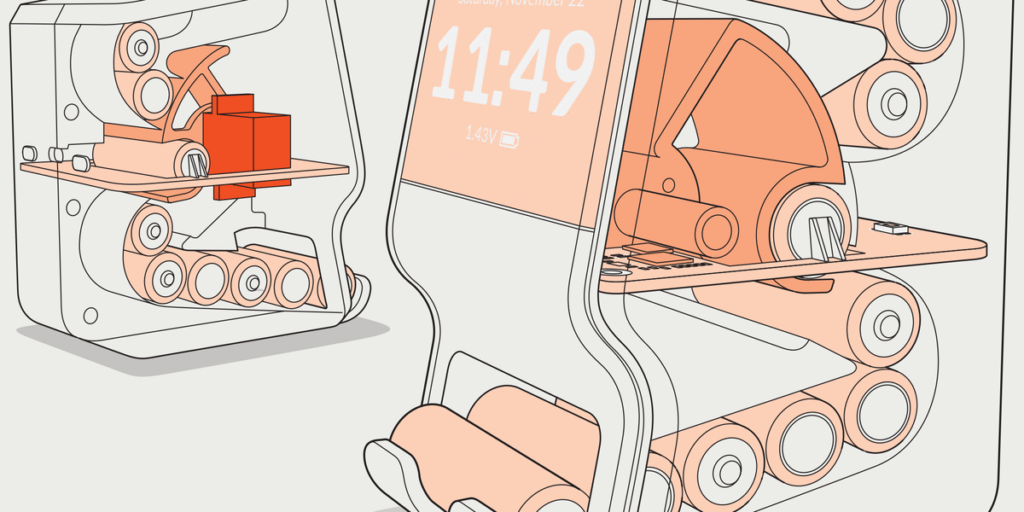

A handful of 3D-printed components [bottom], a servo and display screen [middle] and a single printed circuit board [top] are all that’s wanted for the Spinc charger. James Provost

However it’s additionally true that recharging detachable batteries could be a ache: You must load them right into a charger, which usually holds not more than 4 batteries at a time, and take care to place them in the correct manner. In any other case you get no charging at greatest and irreversible injury to the cell and even overheating at worst.

To ease this ache level, I created the Spinc, a DIY gadget that costs as much as seven NiMH AA batteries at a time and mechanically figures out the polarity of every cell earlier than charging it; when completed, it drops the batteries right into a hopper. You’ll be able to examine on the charging standing by way of a show that doubles as a clock.

In my day job, I work on industrial automobiles as an EE in a midsize German firm. However I got here to this challenge as a consequence of a private curiosity in low-power electronics and after a fruitless try to reap the final dregs of energy from some nonrechargeable batteries. That failure—in a nutshell, my design wanted a buffer battery that needed to be recharged, which defeated the entire goal of the challenge—bought me interested by rechargeable cells.

The toughest a part of creating the Spinc was a self-imposed problem. I wished the charger to be compact and intuitive to make use of. This meant spending plenty of time perfecting the mechanism that takes a battery from the highest of the charger, locations and holds it between two electrodes whereas charging, after which drops the battery out the underside earlier than resetting and grabbing the subsequent cell. Numerous cautious iterations later, I had a set of seven 3D-printer recordsdata to create the components that assemble to type the case and mechanism of the Spinc. To that, you simply want so as to add the show, servo motor, and a printed circuit board with all of the remaining elements, plus an infrared proximity sensor that detects when a battery has been inserted and is able to be positioned between the charging electrodes.

To permit the battery to be charged no matter which manner it’s put into the charger, I used a basic H-bridge circuit, which is often used to let DC motors run in both route, with just a few modifications that allow it work at low voltages.

I made a decision to make use of a devoted built-in circuit to handle the precise charging, with thermistors to be careful for overheating. Whereas I might have used a microcontroller and written my very own software program to observe the battery, NiMH cells have a really flat charging curve, and it’s simple to overshoot the charging cycle. Utilizing an IC saved me from plenty of testing, and likewise gave me the power to make use of a fast-charging mode.

Nonetheless, it didn’t save me from some trial and error. The primary charger IC I used was attractively compact at 2 by 2 millimeters. Nonetheless, after I tried charging an AA battery, I found that the producer assumed the top person can be charging two to 4 batteries at a time, all connected in sequence. Charging only a single battery meant the IC’s linear voltage regulator needed to dissipate extra warmth than supposed, and it shortly burned the chip out. I finally discovered a considerably bigger (5.15 by 4.4 mm) charger IC that makes use of a switched-mode regulator and will deal with the job. Discovering that IC took some time, although, as the recognition of lithium batteries has diminished the provision of supporting elements for NiMH.

The charging curve of NiMH follows a sluggish curve, with the battery’s voltage displaying a dip of simply 2 millivolts when totally charged, which is well overshot and will result in cell injury.James Provost

The charging curve of NiMH follows a sluggish curve, with the battery’s voltage displaying a dip of simply 2 millivolts when totally charged, which is well overshot and will result in cell injury.James Provost

The charger IC is related to an RP2040 microcontroller, which experiences the battery standing on an LCD show. The RP2040 can be chargeable for monitoring the proximity sensor and driving the servo that controls the interior feed mechanism, in addition to responding to the Spinc’s push-button controls, which allow you to set the clock and begin charging the batteries. The complete gadget is powered by way of a USB-C socket.

Many of the electronics are surface-mounted on a PCB that has a big middle cutout to permit the batteries to go by means of it. I designed the PCB in KiCad and had it fabricated by JLCPCB. To make it simpler to manufacture the boards accurately, I didn’t attempt to specify 90-degree angles for the corners of the middle cutout. As an alternative, I went with rounded corners, that are simpler for the reducing tooling to observe.

The result’s a desktop charger that’s as handy to make use of as attainable. A full set of PCB schematics, invoice of supplies, 3D printer recordsdata, and firmware recordsdata can be found from the project page on GitHub. I hope it helps make sure that everytime you want a freshly charged NiMH battery, there’s one proper at hand!

From Your Web site Articles

Associated Articles Across the Net