So far as I could make out, Amazon’s warehouses are extremely structured, extraordinarily organized, very tidy, absolute raging messes. Every thing in an Amazon warehouse is (often) precisely the place it’s presupposed to be, which is often jammed into some pseudorandom cloth bin the dimensions of a shoebox together with a bunch of different pseudorandom crap. Someway, this seems to be essentially the most space- and time-efficient method of doing issues, as a result of (as we’ve written about before) it’s important to take into account the method of stowing objects away in a warehouse in addition to the method of choosing them, and that entails some compromises in favor of house and velocity.

For people, this isn’t a lot of an issue. When somebody orders one thing on Amazon, a human can root round in these bins, shove some issues out of the way in which, after which pull out the merchandise that they’re on the lookout for. That is precisely the form of factor that robots are usually horrible at, as a result of not solely is that this course of barely totally different each single time, it’s additionally very arduous to outline precisely how people go about it.

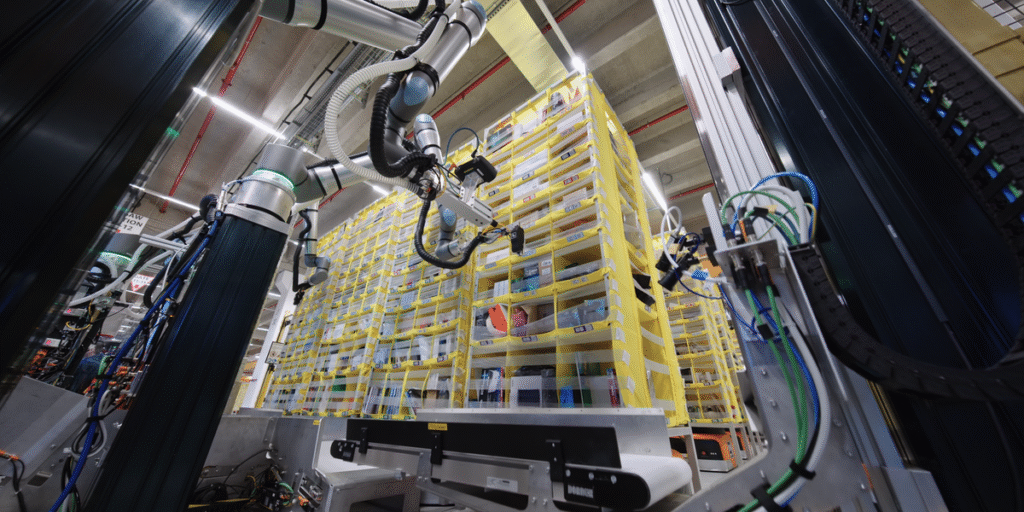

As you would possibly count on, Amazon has been working very very arduous on this choosing drawback. Immediately at an occasion in Germany, the corporate introduced Vulcan, a robotic system that may each stow and choose objects at human(ish) speeds.

Final time we talked with Aaron Parness, the director of utilized science at Amazon Robotics, our conversation was focused on stowing—placing objects into bins. As a part of in the present day’s announcement, Amazon revealed that its robots are actually slightly faster at stowing than the common human is. However within the stow context, there’s a restricted quantity {that a} robotic actually has to grasp about what’s really occurring within the bin. Basically, the stowing robotic’s job is to squoosh no matter is at the moment in a bin as far to 1 aspect as potential as a way to make sufficient room to cram a brand new merchandise in. So long as the robotic is no less than considerably cautious to not crushify something, it’s a comparatively simple process, no less than in comparison with choosing.

The alternatives made when an merchandise is stowed right into a bin will have an effect on how arduous it’s to get that merchandise out of that bin afterward—that is known as “bin etiquette.” Amazon is making an attempt to be taught bin etiquette with AI to make choosing extra environment friendly.Amazon

The defining drawback of choosing, so far as robots are involved, is sensing and manipulation in litter. “It’s a naturally contact-rich process, and now we have to plan on that contact and react to it,” Parness says. And it’s not sufficient to resolve these issues slowly and punctiliously, as a result of Amazon Robotics is making an attempt to place robots in manufacturing, which signifies that its techniques are being straight in comparison with a not-so-small military of people who’re doing this very same job very effectively.

“There’s a brand new science problem right here, which is to determine the fitting merchandise,” explains Parness. The factor to grasp about figuring out objects in an Amazon warehouse is that there are a lot of them: one thing like 400 million distinctive objects. One single ground of an Amazon warehouse can simply include 15,000 pods, which is over one million bins, and Amazon has a number of hundred warehouses. It is a lot of stuff.

In principle, Amazon is aware of precisely which objects are in each single bin. Amazon additionally is aware of (once more, in principle), the load and dimensions of every of these objects, and doubtless has some footage of every merchandise from earlier occasions that the merchandise has been stowed or picked. It is a nice place to begin for merchandise identification, however as Parness factors out, “We now have plenty of objects that aren’t characteristic wealthy—think about all the totally different belongings you would possibly get in a brown cardboard field.”

Muddle and Contact

As difficult as it’s to accurately determine an merchandise in a bin that could be stuffed to the brim with almost an identical objects, a good larger problem is definitely getting that merchandise that you just simply recognized out of the bin. The {hardware} and software program that people have for doing this process is unmatched by any robotic, which is all the time an issue, however the true complicating issue is coping with objects which are all mixed in in a small cloth bin. And the choosing course of itself entails extra than simply extraction—as soon as the merchandise is out of the bin, you then must get it to the following order-fulfillment step, which implies dropping it into one other bin or placing it on a conveyor or one thing.

“Once we had been initially beginning out, we assumed we’d have to hold the merchandise over a long way after we pulled it out of the bin,” explains Parness. “So we had been pondering we would have liked pinch greedy.” A pinch grasp is whenever you seize one thing between a finger (or fingers) and your thumb, and no less than for people, it’s a flexible and dependable method of grabbing all kinds of stuff. However as Parness notes, for robots on this context, it’s extra sophisticated: “Even pinch greedy isn’t best as a result of when you pinch the sting of a guide, or the tip of a plastic bag with one thing inside it, you don’t have pose management of the merchandise and it could flop round unpredictably.”

Sooner or later, Parness and his workforce realized that whereas an merchandise did have to maneuver farther than simply out of the bin, it didn’t really must get moved by the choosing robotic itself. As a substitute, they got here up with a lifting conveyor that positions itself straight exterior of the bin being picked from, so that every one the robotic has to do is get the merchandise out of the bin and onto the conveyor. “It doesn’t look that swish proper now,” admits Parness, but it surely’s a intelligent use of {hardware} to considerably simplify the manipulation drawback, and has the aspect good thing about permitting the robotic to work extra effectively, because the conveyor can transfer the merchandise alongside whereas the arm begins engaged on the following choose.

Amazon’s robots have totally different strategies for extracting objects from bins, utilizing totally different gripping {hardware} relying on what must be picked. The kind of finish effector that the system chooses and the greedy strategy depend upon what the merchandise is, the place it’s within the bin, and likewise what it’s subsequent to. It’s a sophisticated planning drawback that Amazon is tackling with AI, as Parness explains. “We’re beginning to construct foundation models of things, together with properties like how squishy they’re, how fragile they’re, and whether or not they are likely to get caught on different objects or no. So we’re making an attempt to be taught these issues, and it’s early stage for us, however we expect reasoning about merchandise properties goes to be essential to get to that stage of reliability that we’d like.”

Reliability needs to be superhigh for Amazon (and with many different industrial robotic deployments) just because small errors multiplied over large deployments end in an unacceptable quantity of screwing up. There’s a really, very long tail of surprising issues that Amazon’s robots would possibly encounter when making an attempt to extract an merchandise from a bin. Even when there’s some notably bizarre bin scenario which may solely present up as soon as in one million picks, that also finally ends up occurring many occasions per day on the size at which Amazon operates. Thankfully for Amazon, they’ve bought people round, and a part of the rationale that this robotic system might be efficient in manufacturing in any respect is that if the robotic will get caught, and even simply sees a bin that it is aware of is more likely to trigger issues, it could actually simply hand over, route that exact merchandise to a human picker, and transfer on to the following one.

The opposite new approach that Amazon is implementing is a form of fashionable strategy to “visual servoing,” the place the robotic watches itself transfer after which adjusts its motion primarily based on what it sees. As Parness explains: “It’s an essential functionality as a result of it permits us to catch issues earlier than they occur. I believe that’s in all probability our greatest innovation, and it spans not simply our drawback, however issues throughout robotics.”

A (Extra) Automated Future

Parness was very clear that (for higher or worse) Amazon isn’t fascinated with its stowing and picking robots by way of changing people utterly. There’s that lengthy tail of things that want a human contact, and it’s frankly arduous to think about any robotic-manipulation system succesful sufficient to make no less than occasional human assist pointless in an surroundings like an Amazon warehouse, which someway manages to maximise group and chaos on the identical time.

These stowing and choosing robots have been present process stay testing in an Amazon warehouse in Germany for the previous 12 months, the place they’re already demonstrating methods by which human employees may straight profit from their presence. For instance, Amazon pods might be as much as 2.5 meters tall, that means that human employees want to make use of a stepladder to succeed in the very best bins and bend down to succeed in the bottom ones. If the robots had been primarily tasked with interacting with these bins, it could assist people work quicker whereas placing much less stress on their our bodies.

With the robots up to now managing to maintain up with human employees, Parness tells us that the emphasis going ahead shall be totally on getting higher at not screwing up: “I believe our velocity is in a extremely great spot. The factor we’re targeted on now could be getting that final little bit of reliability, and that shall be our subsequent 12 months of labor.” Whereas it could seem to be Amazon is optimizing for its personal very particular use instances, Parness reiterates that the larger image right here is utilizing each final a type of 400 million objects jumbled into bins as a singular alternative to do basic analysis on quick, dependable manipulation in complicated environments.

“If you happen to can construct the science to deal with excessive contact and excessive litter, we’re going to make use of it in every single place,” says Parness. “It’s going to be helpful for the whole lot, from warehouses to your personal dwelling. What we’re engaged on now are simply the primary issues which are forcing us to develop these capabilities, however I believe it’s the way forward for robotic manipulation.”

From Your Website Articles

Associated Articles Across the Net