At an occasion in Dortmund, Germanyat present, Amazon introduced a brand new robotic system referred to as Vulcan, which the corporate is looking “its first robotic system with a real sense of contact—designed to rework how robots work together with the bodily world.” Within the quick to medium time period, the bodily world that Amazon is most involved with is its warehouses, and Vulcan is designed to help (or take over, relying in your perspective) with stowing and choosing objects in its cell robotic stock system.

In two upcoming papers in IEEE Transactions on Robotics, Amazon researchers describe how each the stowing and choosing facet of the system operates. We lined stowing in detail a few years in the past, after we spoke with Aaron Parness, the director of utilized science at Amazon Robotics. Parness and his staff have made loads of progress on stowing since then, enhancing pace and reliability over greater than 500,000 stows in operational warehouses to the purpose the place the typical stowing robotic is now barely quicker than the typical stowing human. We spoke with Parness to get an replace on stowing, in addition to an in-depth have a look at how Vulcan handles choosing, which you will discover on this separate article. It’s a a lot totally different drawback, and effectively price a learn.

Optimizing Amazon’s Stowing Course of

Stowing is the method by which Amazon brings merchandise into its warehouses and provides them to its stock so that you could organize them. Not surprisingly, Amazon has gone to excessive lengths to optimize this course of to maximise effectivity in each area and time. Human stowers are introduced with a mobile robotic pod full of material cubbies (bins) with elastic bands throughout the entrance of them to maintain stuff from falling out. The human’s job is to discover a promising area in a bin, pull the plastic band apart, and stuff the factor into that area. The merchandise’s new house is recorded in Amazon’s system, the pod then drives again into the warehouse, and the subsequent pod comes alongside, prepared for the subsequent merchandise.

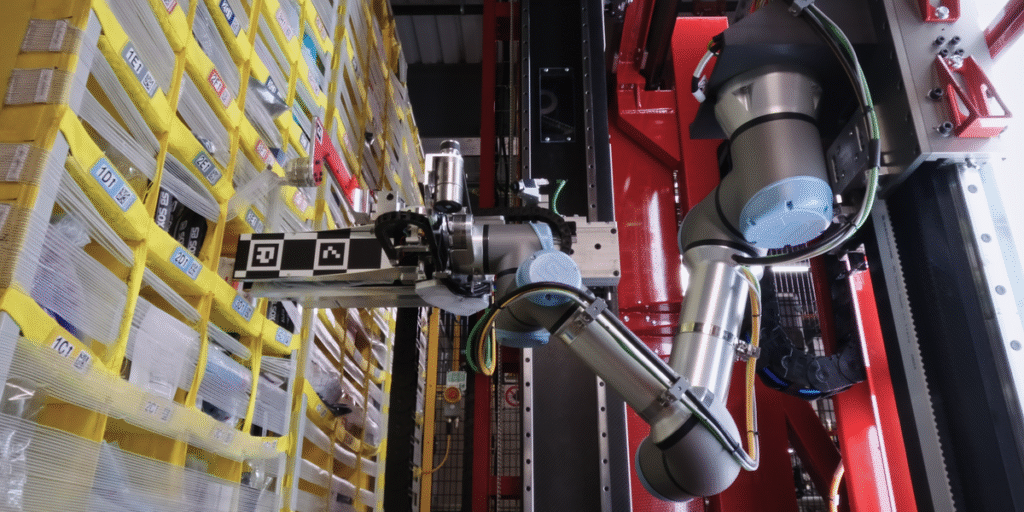

Totally different manipulation instruments are used to work together with human-optimized bins.Amazon

The brand new paper on stowing consists of some fascinating numbers about Amazon’s inventory-handling course of that helps put the size of the issue in perspective. Greater than 14 billion objects are stowed by hand yearly at Amazon warehouses. Amazon is hoping that Vulcan robots will have the ability to stow 80 % of these things at a charge of 300 objects per hour, whereas working 20 hours per day. It’s a really, very excessive bar.

After loads of follow, Amazon’s robots are actually fairly good on the stowing job. Parness tells us that the stow system is working thrice as quick because it was 18 months in the past, which means that it’s really slightly bit quicker than a mean human. That is thrilling, however as Parness explains, knowledgeable people nonetheless put the robots to disgrace. “The quickest people at this job are like Olympic athletes. They’re far quicker than the robots, and so they’re in a position to retailer objects in pods at a lot greater densities.” Excessive density is vital as a result of it signifies that extra stuff can match into warehouses which might be bodily nearer to extra folks, which is very related in city areas the place area is at a premium. The very best people can get very inventive relating to this bodily three-dimensional “Tetris-ing,” which the robots are nonetheless engaged on.

The place robots do excel is planning forward, and that is possible why the typical robotic stower is now in a position to outpace the typical human stower—Tetris-ing is a psychological course of, too. In the identical method that good Tetris gamers are occupied with the place the subsequent piece goes to go, not simply the present piece, robots are in a position to leverage much more info than people can to optimize what will get stowed the place and when, says Parness. “Whenever you’re an individual doing this job, you’ve bought a buffer of 20 or 30 objects, and also you’re searching for a chance to suit these objects into totally different bins, and having to recollect which merchandise may go into which area. However the robotic is aware of the entire properties of all of our objects without delay, and we are able to additionally have a look at the entire bins on the identical time together with the bins within the subsequent couple of pods which might be arising. So we are able to do that optimization over the entire set of knowledge in 100 milliseconds.”

Primarily, robots are much better at optimization inside the planning facet of Tetrising, whereas people are (nonetheless) much better on the manipulation facet, however that hole is closing as robots get extra skilled at working in litter and speak to. Amazon has had Vulcan stowing robots working for over a 12 months in stay warehouses in Germany and Washington state to gather coaching information, and people robots have efficiently stowed lots of of hundreds of things.

Stowing is in fact solely half of what Vulcan is designed to do. Selecting affords every kind of distinctive challenges too, and you may learn our in-depth dialogue with Parness on that subject right here.

From Your Website Articles

Associated Articles Across the Internet