CADmore Metal has launched a contemporary tackle 3D printing steel elements to the North American market often called cold metal fusion (CMF). John Carrington, the corporate’s CEO, claims CMF produces stronger 3D printed steel elements which are cheaper and quicker to make. That features titanium elements, which have traditionally triggered hassle for 3D printers.

3D printing has used metals included aluminum, powdered metal, and nickel alloys for some time. Whereas titanium elements are in excessive demand in fields similar to aerospace and health care as a consequence of their superior strength-to-weight ratio, corrosion resistance, and their suitability for advanced geometries, the steel has offered challenges for 3D printers.

Titanium turns into extra reactive at excessive temperatures and tends to crack when the printed half cools. It could actually additionally turn out to be brittle because it absorbs hydrogen, oxygen, or nitrogen in the course of the printing course of. Carrington says CMF overcomes these points.

“Our main clients have a tendency to return from the power, protection, and aerospace industries,” says Carrington. “One massive protection contractor not too long ago switched from conventional 3D printing to CMF as it is going to save them hundreds of thousands and cut back prototyping and elements manufacturing by months.”

How CMF Enhances Titanium 3D Printing Effectivity

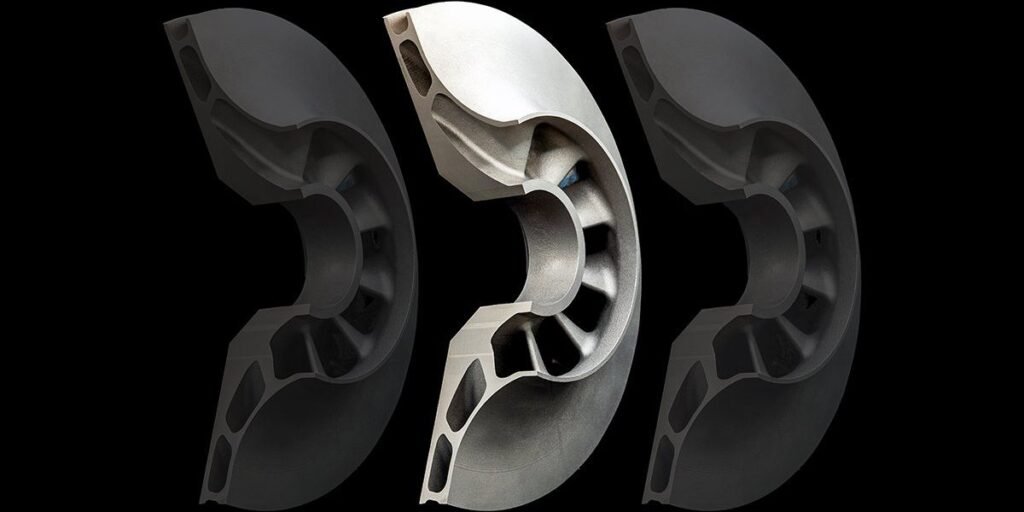

CMF combines the pliability of 3D printing with new powder metallurgy processes to supply energy and higher sturdiness to elements made out of titanium and lots of different metals and alloys. The method makes use of a mix of proprietary steel powder and polymer binding brokers which are fused layer by layer to create high-strength steel elements.

The method begins like some other 3D printing project: A digital file that represents the specified 3D object directs the actions of a normal industrial 3D printer in laying down a combination of steel and a plastic binder. A laser flippantly fuses every layer of powder right into a cohesive strong construction. Extra powder is eliminated for reuse.

The place CMF differs is that the preliminary elements generated by this stage of the method are robust sufficient for grinding, drilling, and milling if required. The elements then soak in a solvent to dissolve the plastic binder. Subsequent, they go right into a furnace to burn off any remaining binder, fuse the steel particles, and compact them right into a dense steel part. Floor or ending remedies can then be utilized similar to sharpening and warmth remedy.

“Our chilly steel fusion expertise provides a course of that’s not less than thrice quicker and extra scalable than some other type of 3D printing,” says Carrington. “Per-part costs are typically 50 to 60 p.c lower than various steel 3D printing expertise. We anticipate these costs to go down much more as we scale.”

3D printing with steel powders similar to titanium makes it potential to create elements with advanced geometries.CADmore Metallic

The fabric utilized in CMF was developed by Headmade Materials, a German firm. Headmade holds a patent on this 3D printing feedstock, which has been designed to be used by the prevailing ecosystem of 3D printing machines. CADmore Metallic serves because the unique North American distributor for the steel powders utilized in CMF. The corporate can even function a methods integrator for all the course of by offering the printing and sintering {hardware}, the specialised powders, course of experience, coaching, and technical help.

“We offer steerage on design optimization and integration with present workflows to assist clients maximize the expertise’s advantages,” says Carrington. “If a turbine firm involves us to provide their elements utilizing CMF, we will both construct the elements for them as a service or set them as much as perform their very own manufacturing internally whereas we provide the powder and help.”

With the worldwide 3D printing market now value nearly US $5 billion and predicted to achieve $13 billion by 2035, in response to analyst agency IDTechEx, the arrival of CMF is well timed. CADmore Metallic simply opened North America’s first CMF application center, a virtually 280-square-meter (3,000-square-foot) facility in Columbia, S.C. Carrington says {that a} bigger facility will open in 2026 to make room for extra materials processing and gear.

From Your Web site Articles

Associated Articles Across the Internet